Why use Systematic Layout Planning?

Why use Systematic Layout Planning?

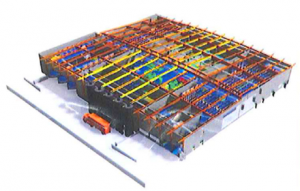

A good plant layout is flexible and creates flow. For over 25 years we have been designing factory layouts in 3D. We are known as the ‘interior architects of the factory’. Drawing a layout may seem simple, but designing a good layout is often a complex process.

A number of factors determine the quality of the final result, including the input from the customer, our experience and adopting a systematic approach. A Value Stream Map, containing the production and logistics concept, forms an important basis for the final layout. In the layouts, we distinguish between floor plans / block layouts and detailed layouts (for example, machine connection, equipment configurations, architectural aspects etc.). The detailed layouts are an important input for the architect, engineers, installers and many other suppliers.

Systematic Layout Planning

SLP, or Systematic Layout Planning, is a proven method to achieve an optimal design of your physical business processes. Ergo-Design integrates SLP into an overall approach in which lean principles, logistics concept and layout options are united in a substantiated design.

Design your future in collaboration with us! 3D Visualisation, Animation and Simulation will be used in a supportive manne

Why use Systematic Layout Planning?

Why use Systematic Layout Planning?