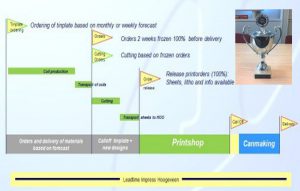

Ardagh

Ardagh – Lead time reduction of 25%

Value Stream Mapping (VSM) formed the basis for discussions about the future, and led to a long-term plan in the form of ‘The Lean Roadmap’. Lead time reduction is essential to minimise waste (Lean) and serve customers on time. As a first step in the roadmap, agreements were made about the production processes: how, when and with what accuracy the (internal) customer would be delivered. Performance indicators (KPIs) have been appointed to monitor these agreements. The results are positive: Substantial improvement in the delivery performance of sub-processes, plan-based working instead of ‘fire-fighting’, a reduction in closing stocks and a reduction of lead times with 25%. Also within the Ardagh Division where Hoogeveen is part of, this performance has not gone unnoticed given the rewarded “Supply Chain Award!