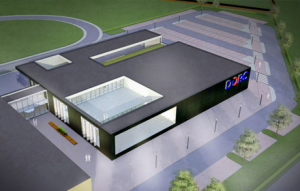

DORC

Masterplan new production facility

In the Master Production Plan, we determined the most logical and efficient flow of production activities, like the incoming goods, the production of medical instruments, the cleanroom and worldwide shipments. The redesign of the production process is analysed by taking into account the partial new factory to facilitate growth.

Daily consultation takes places on the shop floor as part of the Lean implementation. We introduced a standardised method of working and a “supermarket”. Parts for production are always available along the production line to produce according to the customer demand. Parts are automatic replenished if the stock level falls below a certain level. This first phase of Lean is implemented within the production department vitrectomes, a basic tool for eye operations. “The result is a man-efficiency improvement of 40% compared with last year,” says production manager Alwin van de Elburg. “We increased the first-time-right product to 95%.” Van der Elburg expects a trickle-down effect for the other four production departments. The Lean building blocks are coupled to the ‘DORC DNA’ wherein the core values are anchored. “The connection that we have achieved thanks to Ergo-Design, enables us to implement focused improvements. In this way, we can enclose Lean into the DNA of our company.