Unipro

Sustainable factory

Ordered today, delivered tomorrow from a highly sustainable factory in the Netherlands.

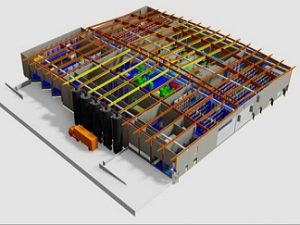

On business park “Stepelerveld” in Haaksbergen, Unipro has opened one of the most sustainable factories in the Netherlands. From mid-2014, the carbon neutral production of adhesives and resin floors is in full swing after H.K.H. Queen Máxima opened the factory. Ergo-Design created a master plan for the establishment of the production process and parallel production lines. Warehouses, silos and tanks are arranged to ensure an optimal flow through the “network factory”. The mixing department with buffer tanks and the filling department can now operate quickly and efficient.

On the old location, Ergo-Design realised a three times shorter lead time up to one day. “We distinguish ourselves in the market with our prompt delivery. Ordered today and delivered tomorrow”, says director Gerben Bouwmeester. “An efficient flow of goods through the plant is a prerequisite. We have no stock, but produce everything customer specific. Together with Ergo-Design, the most logical routing through the factory is made for fast and flexible production. The customer production recipes are constantly changing. Also the mix of products varies widely. In the ‘virtual factory’ of Ergo-Design (Simulation) was it possible to check if the production volumes could be produced in time based on different customer demands. The result is that we can continue to guarantee super-fast delivery.”