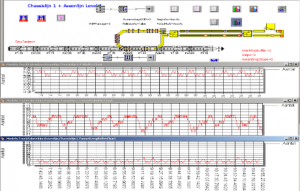

DAF Axis Line

Assurance and savings through Simulation

To test the logistics operation and delivery reliability to the chassis line, Ergo-Design was commissioned by AFT Benelux (www.aft.de) to perform a simulation study. Carrier and lift controls were optimised in the simulation, so that the EMS does not cause ‘line stops’ to the chassis line or axis line. Various ‘what-if’ scenarios were compared. This way, the minimum number of carriers was determined at different production numbers and it was determined how many fork lift drivers were required for a reliable line supply. The simulation model gave DAF certainty about delivery performance and line control. Furthermore, fewer carriers were needed than originally planned. Simulation Costs were thus quickly recouped!